Clogging of soft particles

Xia Hong,

Dandan Chen,

Ken Desmond,

Piotr Habdas,

Anisa Hofert,

Yonglun Jiang,

Pablo Illing,

Meghan Kohne,

Ben Lonial,

Mia Morrell,

Ran Tao,

Haoran Wang,

Madelyn Wilson,

and Eric Weeks

Recent work in collaboration with

Corey O'Hern, Jack Treado, Yuxuan Cheng, Shivnag Sista, William Wang (Yale),

and Mark Shattuck (CCNY)

Lab Home --

People --

Experimental

facilities --

Publications

--

Experimental

pictures

-- Links

This page describes work published in:

- "Clogging of soft particles in 2D

hoppers"

X Hong, M Kohne, M Morrell, H Wang, & ER Weeks,

Phys. Rev. E 96, 062605 (2017). -- draft of an erratum (January 2026)

- "Soft particle clogging in two-dimensional hoppers"

R Tao, M Wilson, & ER Weeks, Phys. Rev. E 104, 044909 (2021) -- draft of an erratum (January 2026)

- "Clogging and avalanches in quasi-two-dimensional emulsion

hopper flow"

X Hong, KW Desmond, D Chen, & ER Weeks, Phys. Rev. E 105, 014603 (2022)

- "Hopper flows of deformable

particles"

Y Cheng, JD Treado, BF Lonial, P Habdas, ER Weeks, MD Shattuck,

and CS O'Hern, Soft Matter 18, 8071-8086 (2022)

- "Flow and clogging of capillary droplets"

Y Cheng, BF Lonial, S Sista, DJ Meer, A Hofert, ER Weeks, MD

Shattuck, and CS O'Hern, Soft Matter 20, 8036-8051 (2024).

Correction.

- Xia Hong dissertation

(2017) -- "Flow of quasi-two-dimensional emulsions: Clogging,

avalanches, and dynamics"

- Haoran Wang honors thesis

(2017) -- "Clogging of soft particles in a 2D hopper"

- Anisa Hofert honors thesis

(2020) -- "Flow of quasi-2D emulsion droplets through small openings"

- Ran Tao honors thesis

(2021) -- "Flow and clogging of soft particles in 2D hoppers"

- Ben Lonial honors thesis

(2021) -- "Dynamics of 2-dimensional soft particle flow through hopper"

Clogging occurs in a variety of situations: people exiting a crowded

room, particles passing through a filter, or corn exiting the bottom of

a silo. In general, you can think of clogging as occuring when

a dense collection of objects tries to leave a container through

a small opening. Often, there is a chance that the objects can

form an arch and block the ones behind them from exiting -- for example,

the glass marbles in the picture below.

(photo from Ran Tao.)

Clogging has been studied for decades, mostly by engineers who need

to understand solid particles flowing out of containers -- think corn,

coal, gravel, etc. Our work has focused on soft particles such as

oil droplets and hydrogel particles, as shown in the next two pictures:

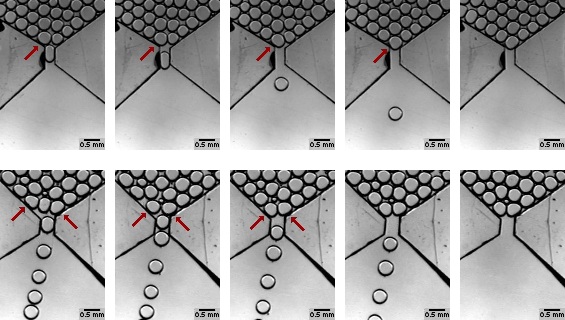

| Picture at right: Oil

droplets forming clogs as they exit a funnel. The

droplets are between two parallel glass plates, so

they are deformed into pancakes. Click

here to see a movie of the clogging event shown in the

bottom row of images.

(Photos and video from Xia Hong.)

|

|

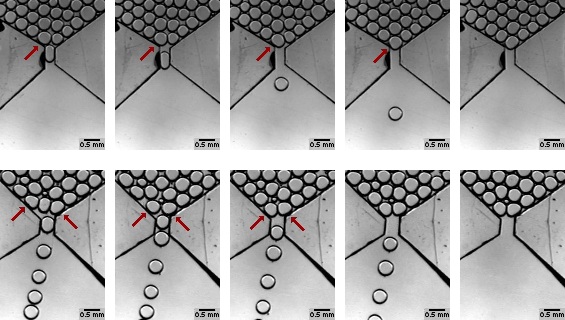

| Picture at right: Hydrogel

particles forming a clog. The particles are about 1.5 cm in diameter, and

the exit opening width is 2.88 cm. The apparatus is tilted so

that it is nearly horizontal to reduce

the driving force of gravity (10 degrees inclined from horizontal).

(Photo from Mia Morrell.)

|

|

|

Inspired by the

work of Kiwing To, Pik-Yin Lai, and H. K. Pak, we examine

the flow of these various types of particles as they drained

out of quasi-two-dimensional hoppers (the technical term

for these funnels shown in the pictures above). In all cases,

we control the opening size w and compare that to

the particle diameter d. If w/d is small, then

the system always clogs: the particles form an arch at the exit

and flow permanently stops. If w/d is large, then the

system never clogs: all the particles exit through the bottom.

For intermediate values of w/d, sometimes the system

clogs and sometimes not.

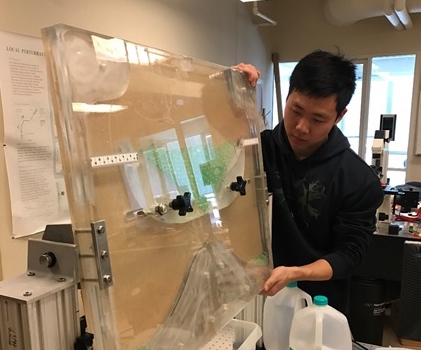

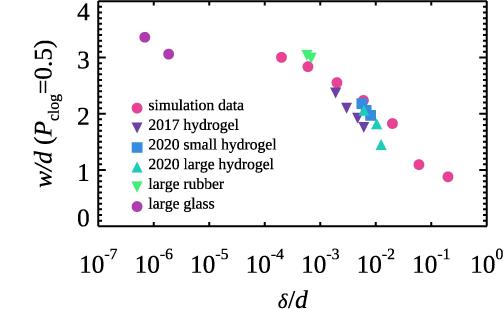

We do a bunch of experiments at different values of w/d and

measure the clogging probability, which leads to the graphs

shown at right. The top graph is for oil droplets: these rarely

clog, and require opening sizes less than about 1.5 times a

particle diameter to see clogging. The middle graph is for

hydrogel particles. We vary gravity by changing the tilt

of the experiment relative to vertical; the image below

shows Haoran tilting an older version of our sample chamber. For

a fully vertical experiment, it is harder to clog: this is the left-most

triangle symbols labeled 1.0g in the graph. For a nearly horizontal

experiment, it is much easier to clog: this is the right-most

curve labeled 0.17g in the graph.

|

|

The bottom graph shows our simulation data. We use

the

Durian

bubble model to simulate the flow of soft particles;

you can

click here to download our IDL code for these simulations.

Click here to see an animated

GIF movie of one of our

simulations. And this is a close-up movie

of the same data, with inter-droplet

forces highlighted. For these movies, w/d=2.2 and

the data correspond to the blue circles of the bottom clogging graph.

The simulation lets us vary gravity by three orders of magnitude. As

with the hydrogel particles, the lower the gravity, the easier it is

to clog -- we can get clogging even with large values of w/d, more

than three diameters wide.

The main idea here is that when gravity is big (or the particles are

very soft), the weight of the particles on top will make the

particles underneath deform. The soft particles can't form an arch, or

at least, if they try to form an arch, the weight causes that arch

to break. But when gravity is small (or the particles are harder),

it is easier to form a permanent arch that can support the weight

of the particles above it.

|

We need to see if the experiments and simulations are giving similar

results. To do this, we measure how much a single particle deforms

under its own weight. That's some distance delta, and we

divide that by the particle diameter d so that we have a

nondimensional quantity. We then determine the value of w/d for

which clogging occurs half the time for

each experiment or simulation, and plot that special value

of w/d as a function of delta/d. The

data are shown at right. The 2017 hydrogel data are from our 2017

paper (Hong et al), and the other data are from our 2021 paper (Tao et al).

|

|

What's fun about our results is that they are the exact opposite

of what people have seen for years with hard particles! With

hard particles, there's a phenomenon called "faster is slower."

This is easiest to understand with people trying to leave a crowded

room through a narrow doorway. If nobody is in a hurry, then people can

exit fairly efficiently. If people are rushing, then you can form

an arch of people at the doorway, and the crush of people from

behind can prevent the people in the arch from being able to move and

disrupt their arch. Thus, the flow of people out of the room

is actually slower than when people aren't in a hurry.

The key difference is that with people exiting a room,

they are moving somewhat randomly. If they form an arch, they're

going to continue to jostle each other to break free. And

if coal flows out of a container and gets stuck, you'll bang on

the container to break the clog. In this case, the

pressure of coal above will stabilize the arch against being

jostled by your banging on the container. In contrast,

with soft particles, we don't have random jostling or banging.

If a clog forms, it is stable. And instead, if we have

a larger driving force (larger gravity), this causes the

arch particles to deform and rearrange enough to break the

arch and flow will resume.

This does raise the question of whether adding vibrations to our

system will cause it to unclog. Mia Morrell did some experiments

showing that indeed this is the case, although we did not ever

see the "faster is slower" effect.

We did some additional experiments and simulations related to

flowing oil droplets. Briefly, in these cases we allowed the

pressure to build up if the system clogged, until the pressure

causes the arch to break, at which point the pressure drops.

Thus, we never had permanent clogs. Instead, we found that the

flow rate was intermittent, especially when we tried to pump

the droplets at low flow rates. In these cases we'd get a clog

followed by a big avalanche where many droplets flowed out.

When we tried to pump faster, the flow was steadier. We

were able to explain these results in terms of the system

compliance; see the 2022 paper by Xia Hong for details (link

at the top of this page).

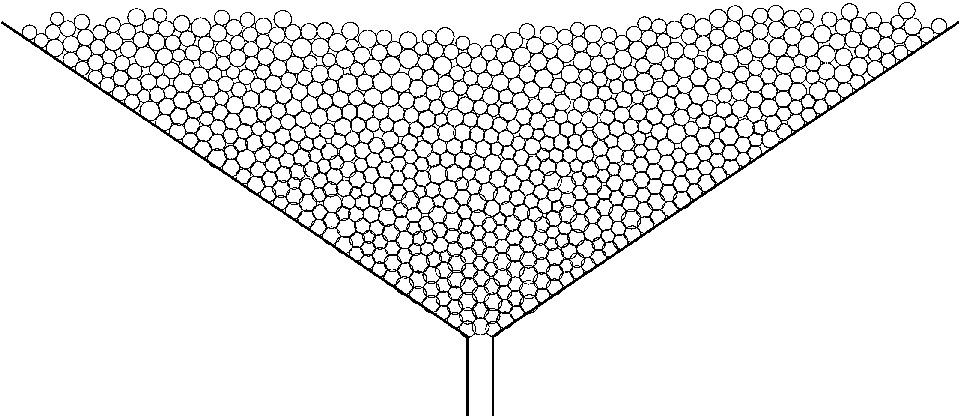

For fun, here's a simulation picture where the clogging occured early on,

when the hopper was nearly full (almost 800 particles):

For more information, please contact

Eric Weeks <weeks(at)physics.emory.edu>